The five-axis servo manipulator is an active operating device that can imitate some of the functions of human hands and arms to grasp, transport or operate objects according to a fixed procedure. Manipulators are industrial machinery that appeared earlier and are modern robots that appeared earlier. Although a bit cumbersome, they can replace human labor to complete the mechanization and automation of production. They can operate in harmful environments to maintain personal safety, although they are not as good as human hands. Sensitive, but it can keep repeating work and labor, without being exhausted, not afraid of risks, and more powerful than human hands. It has been paid attention to by many parts, so it is widely used in machinery manufacturing, metallurgy, electronics, light industry and atomic energy.

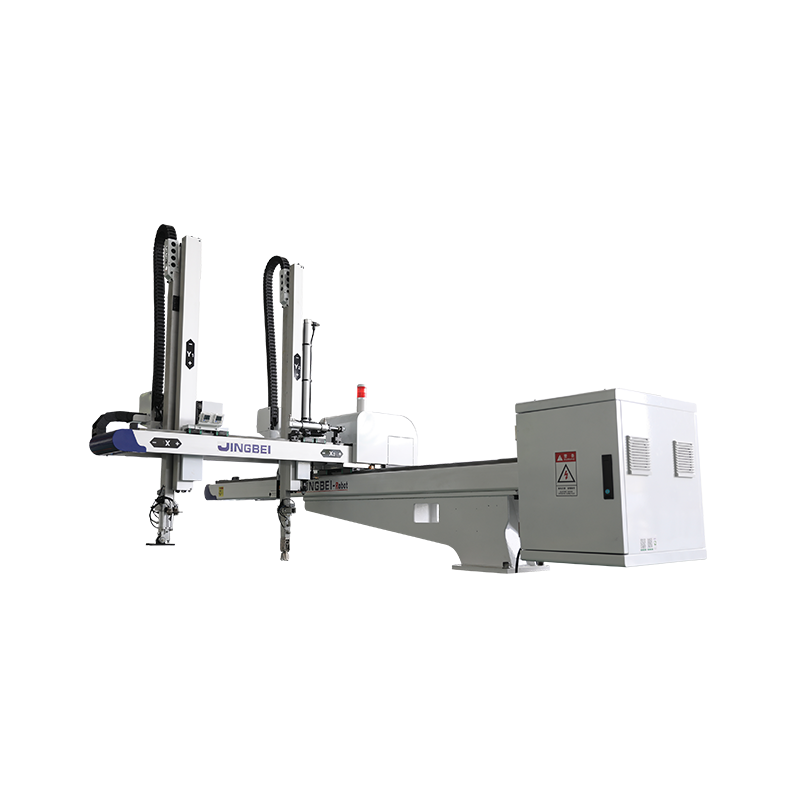

The five-axis servo manipulator is a supplement to the function of the three-axis servo manipulator. By adding a jib to meet the additional pickup requirements of three-plate molds and stacked molds, or adding a servo axis to the main arm to achieve different angle rotations of the jig to meet complex Production requirements. The five-axis servo manipulator moves horizontally, draws and pulls, and the arm is driven by a servo. The arm is double-cut up and down, and the pull-out square structure is movable. The side capital is a servo side posture group, which takes out time and is convenient to adjust the fixture.

Long life, low failure, less take-out time of 1.8S, larger load 10KG (including fixtures and finished products), mainly used for quick take-out or complex take-out applications, especially long products such as automotive products, washing machines, home appliances, etc.

In addition to the five-axis servo manipulator instead of manual use for the finished product and nozzle in the mold of the injection molding machine, it can also be used with the automatic nozzle cutter for the automatic nozzle of the injection molded plastic parts. The whole process does not require personnel to be on duty and reduces labor; this machine is a good helper; Linked with the manipulator on the injection molding machine, the tail can be cut after finishing the beer.

This equipment is widely used in the pre-stage of bottle blowing, such as the nozzle cutting of the embryo body of shampoo bottles, mineral water bottles, oil bottles, baby bottles, etc. Eliminate the tedious process of manually cutting the nozzle. After the injection molding machine has injected the embryo body, the robot clamp is clamped into the nozzle shearing machine. This opportunity automatically cuts the nozzle and clamps the embryo body after the nozzle removal to the conveyor belt for packing.