1. The signal of "Robot arms move up" appears abnormally

Tips and solution: Check if the wires are loose,check if sensory switch is working normally.

2. Proximity switch is too far away from sensory metal

Tips and solution: Adjust the distance between the proximity swith and sensory metal.

3. Injection molding machine Robot arm don't move up enough

Tips and solution: Move the robot arms up to theirs up limit by hand.

4. Alarm "AC servo motor abnormal"

Tips and solution: Check the error number, repair according to error numbers.

5. Injection molding machine robot hit something while moving.

Tips and solution: Check if the sensor lights are on,adjust the sensory distance. Check if there are abnormal things on X axes which scratched the robot arm. Turn off the robot, manually move the robot to the middle of X-axes, then turn on the robot.

6. Injection machine don't thimble out occasionly while using injection molding machine robot automatically

Tips and solution: Wire connection not good, Check Aviation connector if plugged tighten, check if wires loosen.

7. Circuit board has a problem or wire connection wrong

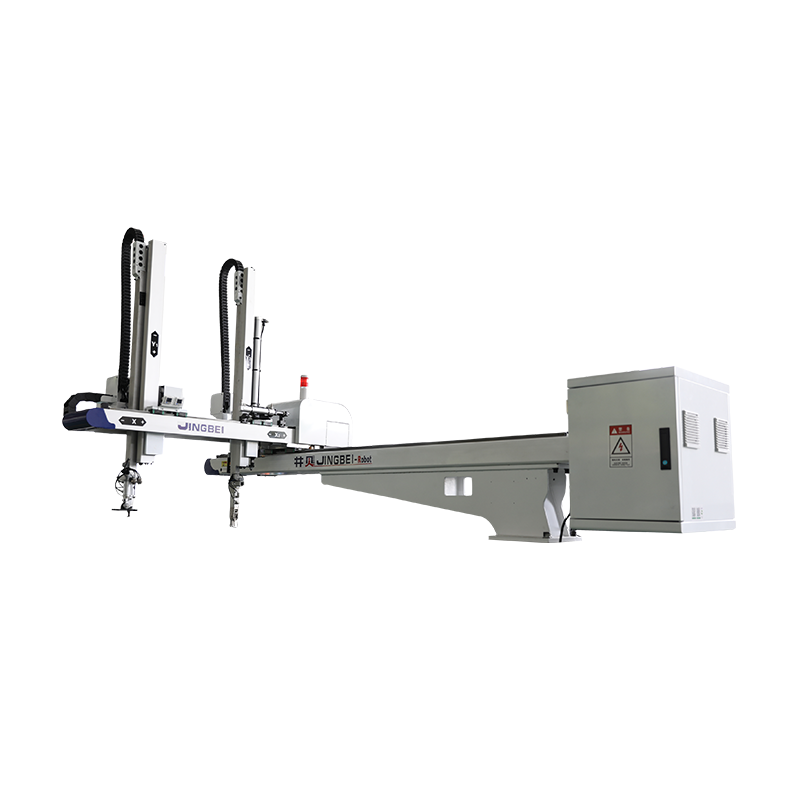

Jingbei Technology (Zhejiang) Co., Ltd. is professional China Robot Arm For Injection Molding Machine Manufacturers and Robot Arm For Injection Molding Machine Factory, our company located in the beautiful Taihu Lake, the center of the Yangtze River Delta, and the industrial belt of Changxing Lijiaxiang Industrial Zone. It is located at the junction of the three provinces of Jiangsu, Zhejiang and Anhui. It is a two-hour economic circle in the Yangtze River Delta. Deep high-speed, south Of Humin Expressway, north of Tuying Avenue, direct access to Taihu Lake Scenic Area, convenient transportation.